BATTLAX

HYPERSPORT S22

Riding on winding roads is about to change.

Technological Highlights

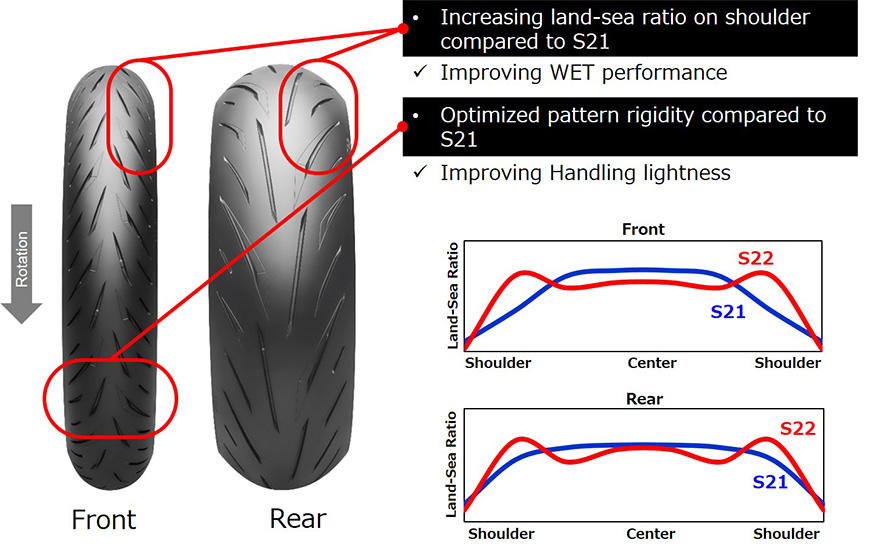

1. New Tread Pattern

To enhance cornering on rainy days, the BATTLAX HYPERSPORT S22 tyre features an increased land-sea ratio on the tyre's shoulder in comparison to the BATTLAX HYPERSPORT S21 tyre, and pattern rigidity has been optimized. These features contribute to improved wet performance and handling lightness.

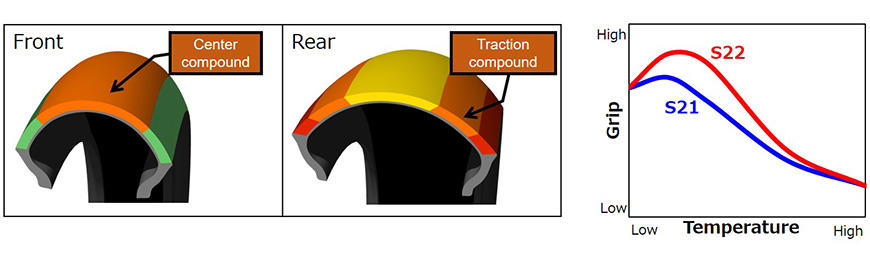

2. New Compound

(1) Optimized Resin Component

In designing the BATTLAX HYPERSPORT S22 tyre, steps were taken to optimize the resin component in order to develop a new compound that can function across a wide range of temperature conditions, including lower temperatures. This allows the tire to deliver higher grip on dry surfaces.

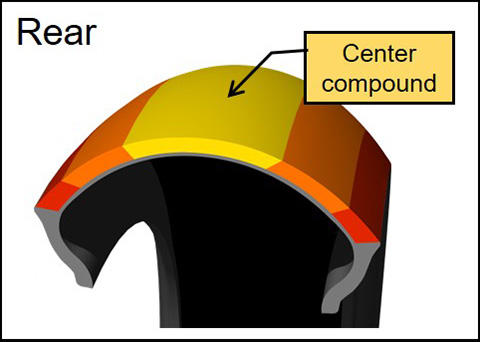

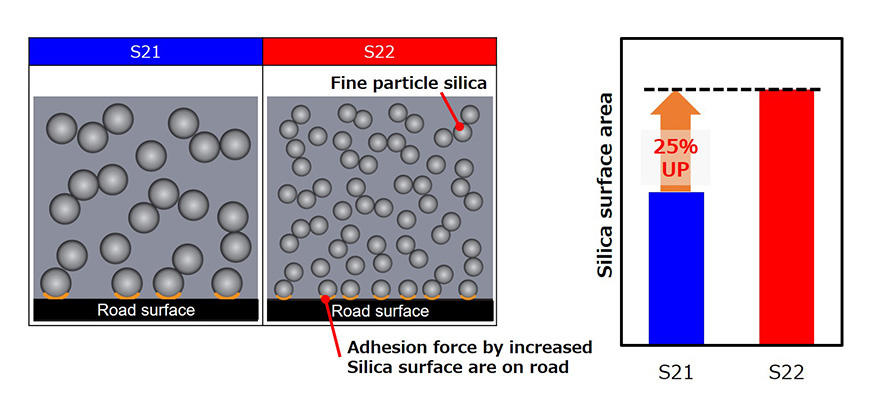

(2) Fine Particle Silica

The centre compound of BATTLAX HYPERSPORT S22 rear tyres utilizes silica comprised of particles that are smaller than those found in conventional tyres to increase the area of the silica in the contact patch, the portion of a tyre that makes contact with road surfaces. This composition enables the BATTLAX HYPERSPORT S22 tyre to better grip the road in wet conditions.

3. Optimized Contact Area

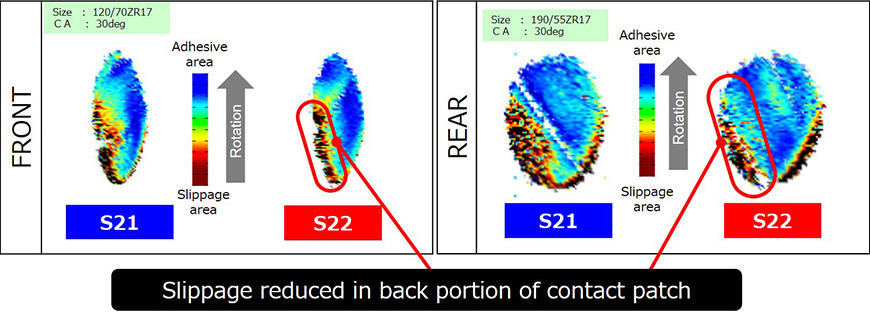

In the development of the BATTLAX HYPERSPORT S22 tyre, Bridgestone employed its proprietary ULTIMAT EYE™ technology,*1 to measure and visualize the behavior of tyre contact patches. This technology has also been used for developing tires for the FIM Endurance World Championship. Bridgestone has reduced the slippage area in the rear part of the tyre's contact patch in comparison to the BATTLAX HYPERSPORT S21 tyre. These changes contribute to improved grip and light handling of the BATTLAX HYPERSPORT S22 tyre while preventing declines in lifespan.

- ULTIMAT EYE™ is Bridgestone's proprietary tyre development technology for measuring and visualizing the behavior of tire contact patches. Conventional tyre development consists of running simulations, building prototypes, and using laboratory measurements as well as actual vehicle tests to verify performance. ULTIMAT EYE™, meanwhile, makes it possible to reproduce high-speed riding conditions that are equivalent to those of an actual vehicle in the laboratory, enabling tyre contact patch behavior to be visualized. Together with conventional vehicle tests, this technology can contribute to improved tyre performance through high-precision analyses and performance verifications with a solid scientific basis.